-

Numero contenuti pubblicati

12944 -

Iscritto il

-

Ultima visita

-

Giorni Massima Popolarità

56

Tipo di contenuto

Forum

Galleria

Calendario

Download

Articoli del sito

Store

Blog

Tutti i contenuti di 4200blu

-

Hyundai Q2 profit jumps 59% as chips crunch eases The strong results come amid an easing of the chip shortage, which helped Hyundai resume overtime and weekend shifts at its domestic plants. SEOUL -- Hyundai Motor posted a rise of 59 percent in second-quarter profit as a weak won currency lifted the value of overseas earnings and demand stayed strong for the South Korean automaker's high-margin SUVs. Net profit climbed to 2.8 trillion won ($2.13 billion) for the April-June period from 1.8 trillion won a year earlier. "A robust sales mix of SUV and Genesis luxury models, reduced incentives from a lower level of inventory, and a favorable foreign exchange environment helped lift revenue in the second quarter, despite the slowdown in sales volume amid an adverse economic environment," Hyundai said in a statement on Thursday. The strong results come amid an easing of a global chip shortage, which helped Hyundai resume overtime and weekend shifts at its domestic plants, offsetting lost vehicle production caused by a nationwide trucker strike in June. "After nearly two years of chip shortages, automakers, including Hyundai, are getting enough chips to produce at nearly full capacity," said Lee Jae-il, an analyst at Eugene Investment & Securities. (ANE)

-

Ford Motor is preparing to cut as many as 8,000 jobs in the coming weeks as the automaker tries to boost profits to fund a push into the electric-vehicle market, according to people familiar with the plan. The eliminations will come in the newly created Ford Blue unit responsible for producing internal combustion engine vehicles, as well as other salaried operations throughout the company, said the people, who asked not to be identified revealing internal discussions. The plan has not yet been finalized and details could still change. The move would mark a significant step in CEO Jim Farley’s plan to cut $3 billion in costs by 2026. He has said he wants to transform Ford Blue into “the profit and cash engine for the entire enterprise.” In March, Farley radically restructured Ford, cleaving its carmaking in two by creating the “Model e” unit to scale up EV offerings and “Ford Blue” to focus on traditional gas burners such as the Bronco SUV. The job cuts are expected to come among Ford’s salaried ranks in a variety of operational functions, according to the people familiar. They may come in phases, but are likely to begin this summer, the people said. Ford employs about 31,000 salaried workers in the U.S., where the bulk of the cuts are expected. Ford declined to comment on possible job cuts, saying that it’s focused on reshaping the organization to capitalize on the growth of electric vehicles. “As part of this, we have laid out clear targets to lower our cost structure to ensure we are lean and fully competitive with the best in the industry,” Chief Communications Officer Mark Truby said in a statement. Farley has said cutting staff is a key to boosting profits, which have evaporated on the electric Mustang Mach-E and other plug-in models amid rising commodity and warranty costs. “We have too many people,” Farley said at a Wolfe Research auto conference in February. “This management team firmly believes that our ICE and BEV portfolios are under-earning.” Ford shares tumbled 39 percent this year through Tuesday, worse than the broader market, amid inflation fears and supply-chain bottlenecks roiling the automotive industry. In March, Farley boosted spending on EVs to $50 billion and set a plan to build 2 million battery-electric vehicles annually by 2026, after selling just 27,140 in the U.S. last year. Last month, Ford’s EV sales rose 77 percent from a year earlier as it rolled out the new electric F-150 Lightning pickup. To finance Ford’s electric ambitions, Farley has said he needs the company’s traditional gasoline-fueled models to make more money. “The funding for that $50 billion, it’s all based on our core automotive operations,” Farley said in a March interview with Bloomberg Television. “That’s why we created a separate group called Ford Blue, because we need them to be more profitable to fund this.” (Bloomberg)

- 204 risposte

-

- 1

-

-

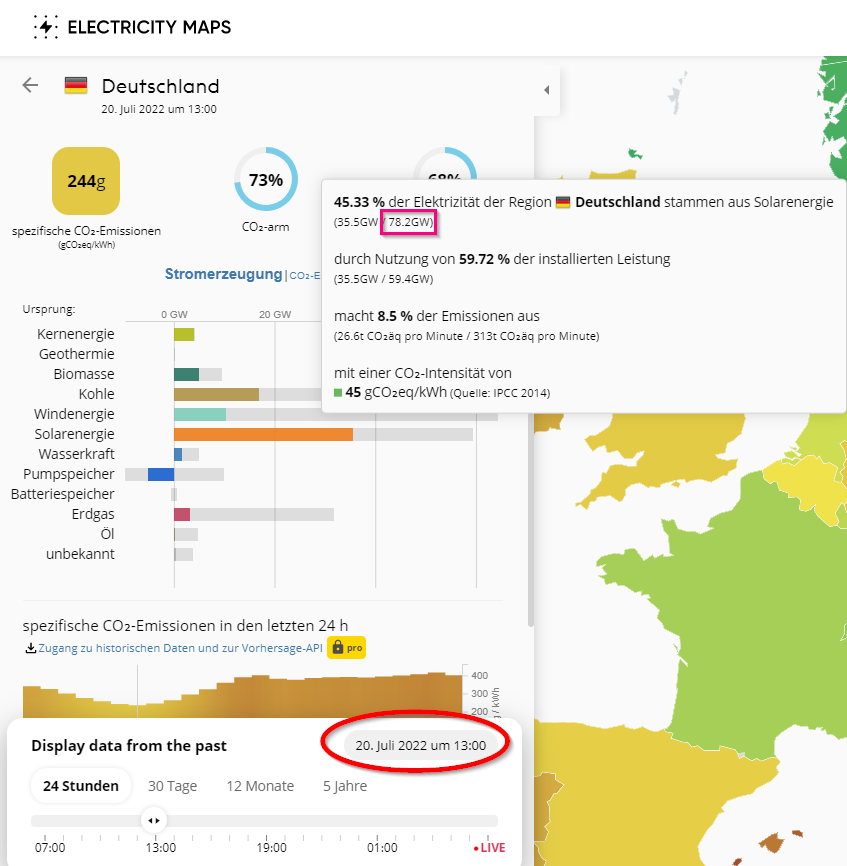

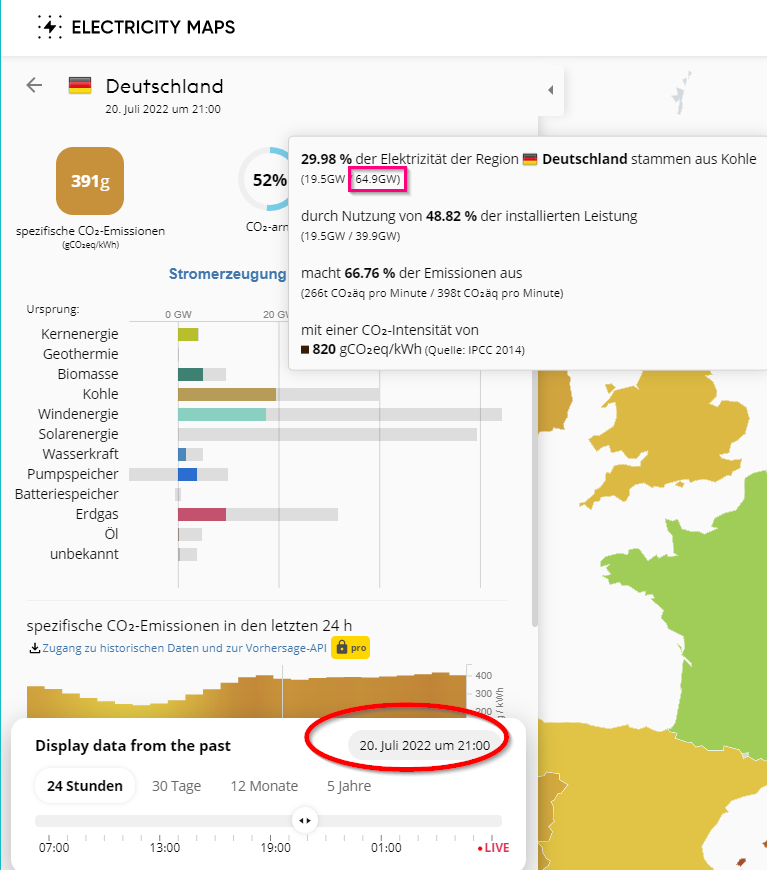

Certo, niente falso, solo con le rinnovabile hai il problema della discontinuita. Sono forte a certi condizioni (orario, meteo), ma ci sono periodi dove non ci sono, ma la industria chinica, metallurgica ecc. lavora 24/7, la automotive almeno con due turni. Cosi hai bisogno di gigantesce volumi di accumulare la energia prodotta nelle condizioni giusti per usare poi quando hai bisogno di usarla. Per esempio ieri, giorni straordinaria con 15h di sole dapertutto in Germania, una cosa che succede forse 20volte al anno, chiaro, in Italia piu spesso) produzione in Germania: Mezzogiorno 13:00: Produzione totale in Germania 78,2GWh, di cui 35,5Gwh solare Ma alla sera 21:00: Produzione totale 64,9GWh, sollare zero, carbonio 19,5GWh Per sostituire questa produzione con carbonio/gas per tutte le notte e giorni piovosi hai bisogno di centinaie di Gwh accumulatori (o idrogeno prodotto con il corrente solare durante i giorni solari con elettrolisi). Certamente non impossibile, ma non fattibile in 3 o 5 anni e costossisimo.

- 4226 risposte

-

- 3

-

-

-

- transizione ecologica

- bev

-

(e 2 altri in più)

Taggato come:

-

La Cina, anche nelle auto elettriche, è forte sulla roba cheap. ....ahh si ??? 🤔 Hai mai visto una Polestar, Zeekr, Xpeng o NIO dal vivo o forse sei entrata nel intero ??

- 4226 risposte

-

- 4

-

-

-

- transizione ecologica

- bev

-

(e 2 altri in più)

Taggato come:

-

Ford has stopped taking orders for the models as deliveries stretch into 2023 because of supply problems. BERLIN -- Ford is severely restricting the availability of its key Fiesta and Focus models for ordering throughout Europe, closing the order books for both models until further notice. This means that only preconfigured models can be ordered until further notice, as the automaker responds to excessively long delivery times, according to a report in Automotive News Europe sister publication Automobilwoche. "Due to the good customer demand, however, also due to the production situation, we currently have delivery times of up to 12 months in some cases for various model series," a Ford spokesperson told Automobilwoche. "We closed free order availability for our dealers on the Ford Focus and Ford Fiesta, among others, some time ago," the spokesman said. "However, we are offering available production volume to our dealers in the form of pre-specified units based on customer demand." He added this is Ford's way of ensuring that customer orders can be fulfilled, and that available production capacity can be used in the best possible way. Markus Thal, the head of the works council in at Ford's factory in Saarlouis, Germany, which builds the Focus, confirmed the unusual measure and said the orders currently being received would already run into 2023. He said it would not currently be possible to deliver a Focus before next spring. According to employee representatives, Ford now expects annual production of only 117,000 Focus cars for the current year, down from 195,000 units originally planned. For 2023, around 143,000 units are currently still planned, according to Thal. However, it is uncertain whether this figure can be achieved, as production is heavily influenced by ongoing supply chain bottlenecks, especially for semiconductors. An additional complicating factor is the situation on the energy market. It is also uncertain how the workforce at the Saarlouis plant will react to the decision by Ford management to build new electric cars in Valencia, Spain, rather than in Saarlouis, adding to workers' concerns about the plant's future.

- 204 risposte

-

- 2

-

-

Secondo me 5 anni avanti non ci sara nessuna macchina a 20.000.-........

- 4226 risposte

-

- 2

-

-

-

- transizione ecologica

- bev

-

(e 2 altri in più)

Taggato come:

-

...direi che le auto del futuro tutti costano molto di piu come gli ultimi anni, indipendente della sorta propulsore. Leggete gli considerazioni attuali di Thomas Schäfer, capo brand VW, che dice che un auto ice Euro7 diventera piu cara tra 3000 e 5000 Euro.

- 4226 risposte

-

- transizione ecologica

- bev

-

(e 2 altri in più)

Taggato come:

-

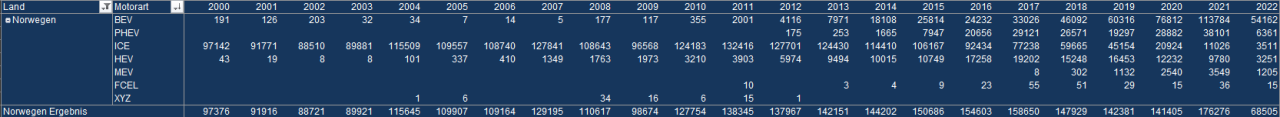

Non ho dubbi che alcuni politici hanno in mente un futuro come @stev66 descrive - con molto meno auto privati e meno traffico motorizzato - , ma se guardiamo a Norvegia, un mercato dove la transizione verso le bev e quasi completa, non si nota una riduzione delle macchine immatricolate totale, il mercato va avanti stabile. Perche nel resto del Europa con qualche anni di ritardo dovrebbe diverso?

- 4226 risposte

-

- 2

-

-

-

- transizione ecologica

- bev

-

(e 2 altri in più)

Taggato come:

-

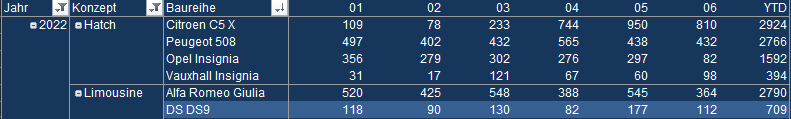

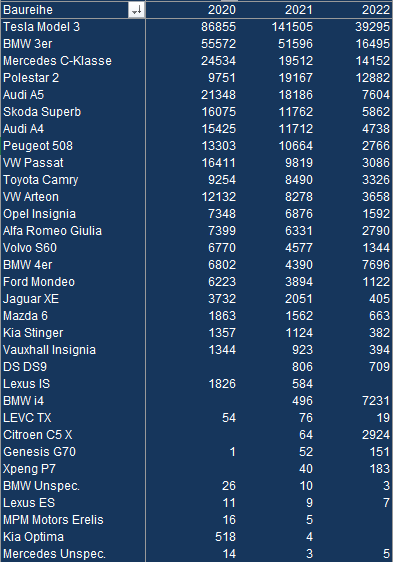

..le cifre sopra sono solo Europa, ma non cambia molto con le cifre globale (anche se il giugno non e ancora completo)

- 36 risposte

-

- stla medium

- seg. d

-

(e 5 altri in più)

Taggato come:

-

Si, credo che si puo vedere cosi, anche se forse e gia piu E come D, a la longue secondo me sostituisce la etron che in prossima generazione sicuramente diventera piu grossa.

- 11 risposte

-

- 1

-

-

- audi q6 sportback e-tron

- audi q6

- (e 5 altri in più)

-

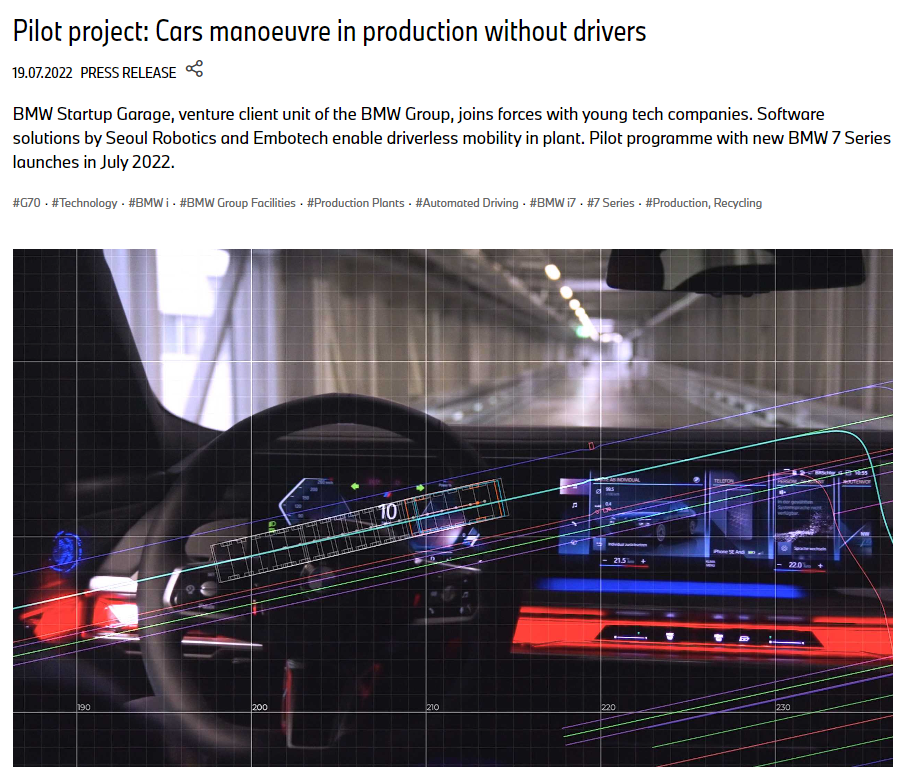

Munich. The BMW Group is launching a unique project that will see cars manoeuvre around production without requiring a driver. The Automated Driving In-Plant project (‘Automatisiertes Fahren im Werk’, AFW) is being realised in collaboration with two startups and will enhance the efficiency of new-vehicle logistics in plants and distribution centres. The aim of the AFW pilot project is for vehicles to move autonomously around logistics areas and assembly – safely, efficiently and without requiring a driver. To make this happen, the BMW Group has been collaborating with Seoul Robotics from South Korea and Embotech from Switzerland. Launching in July 2022 at BMW Group Plant Dingolfing, the new system will first be trialled on two cars incorporating breakthrough technologies: the new BMW 7 Series and the fully electric BMW i7. Automated manoeuvres from first ignition to onward transportation “Automated driving within the plant is fundamentally different from autonomous driving for customers. It doesn’t use sensors in the vehicle. In fact, the car itself is more or less blind and the sensors for manoeuvring them are integrated along the route through the plant,” explains BMW Group project manager Sascha Andree. AFW builds on two key technologies: a sensor infrastructure to support vehicle localisation and detect obstacles in the plant environment, and a drive-planning software that transmits controlled commands to the driverless vehicles via mobile communications. Initially, the vehicles will only move through the assembly area and then to logistics. Fresh off the production line, they will drive themselves to a parking area, ready for their onward journey by train or truck. Essentially, the technology can be used from the moment the cars are capable of driving independently in production – just after the first ignition of the engine, in other words. BMW Startup Garage recruits young companies for the project Seoul Robotics’s lidar detection software uses static monitoring sensors to create a digital twin of the environment, including object classification and vehicle localisation, while Embotech’s drive-planning software steers, brakes, accelerates and parks the driverless vehicles. Routes are calculated in real-time, and rather than needing to be trained or programmed for the current situation, each car is able to respond independently to its surroundings. “This collaboration, with two young startups and an OEM like the BMW Group working together on a single project, is probably the first of its kind,” says HanBin Lee, CEO of Seoul Robotics. It was made possible by the BMW Group’s venture client unit, the BMW Startup Garage. Having discovered Seoul Robotics as a potentially interesting supplier of technologies, the BMW Startup Garage initiated the first proof of concept project, with Sasche Andree and team. After a product demonstration, Embotech was welcomed on board as well. “Without the BMW Startup Garage, we would never have been able to evaluate and test our solution,” says Alexander Domahidi, co-founder and CTO of Embotech. The pilot project will run for several months. Later it will be rolled out further, initially on additional models at Plant Dingolfing and later in other plants as well. Venture client approach nurtures innovativeness at the BMW Group Automated Driving In-Plant is a ground-breaking project in the automotive industry and just one of many success stories by the BMW Startup Garage. The venture client model has been in operation since 2015, working with the startups to evaluate their potential projects. It is a leading instrument for corporate venturing and seeks to purchase their products early on rather than taking over the startups themselves. The BMW Startup Garage has successfully carried out more than 150 pilot projects with leading startups with this approach, with a cumulative investment volume of more than US$ 4.5 billion. (BMW Group)

- 255 risposte

-

- rolls-royce

- scelte strategiche

-

(e 2 altri in più)

Taggato come:

-

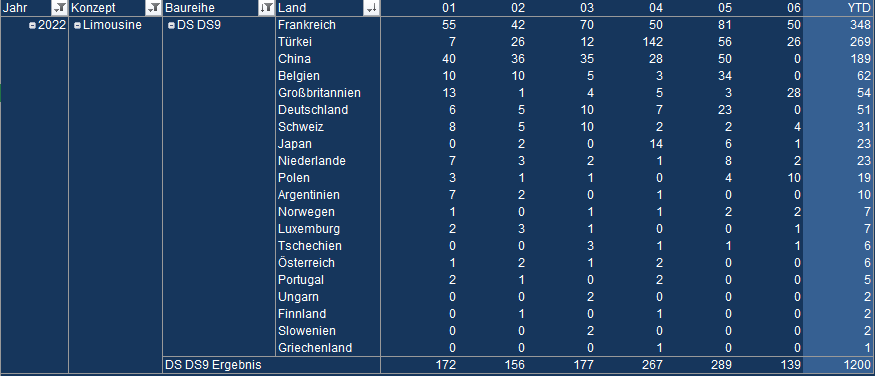

...si, avrebbe una certa logica economica sicuramente non falsa. Il volume complessivo di queste D di Stellantis in un semestre fa Tesla solo con la 3 in un mese.

- 36 risposte

-

- 1

-

-

- stla medium

- seg. d

-

(e 5 altri in più)

Taggato come:

-

...sara posizionato sotto la Etron e sopra la Q4.

- 11 risposte

-

- 1

-

-

- audi q6 sportback e-tron

- audi q6

- (e 5 altri in più)

-

- 36 risposte

-

- 1

-

-

- stla medium

- seg. d

-

(e 5 altri in più)

Taggato come:

-

per esempio qui: https://europe.autonews.com/automakers/vws-software-unit-be-streamlined-cariad-head-says

- 216 risposte

-

- 2

-

-

- porsche

- porsche news

-

(e 3 altri in più)

Taggato come:

-

..altra vittima dei problemi alla CARIAD.

- 216 risposte

-

- 1

-

-

- porsche

- porsche news

-

(e 3 altri in più)

Taggato come:

-

..il piano B sara che tutti noi stupidi europei comprano macchine ice cinese dopo il 2035 perche la nostra industria automotive piu o meno non esiste piu.

- 4226 risposte

-

- 8

-

-

-

- transizione ecologica

- bev

-

(e 2 altri in più)

Taggato come:

-

..si certo, penso anch'io, ma non credo che in realta cambiera cosi veloce. Se penso a qualche parte di Baviera bassa, sud d'Italia, sud di Francia (e qui non i grandi metropole come Marseille o Toulon), il hinterland catalana ecc ecc, poi secondo me questo processo durera molto piu lungo.

- 4226 risposte

-

- 2

-

-

- transizione ecologica

- bev

-

(e 2 altri in più)

Taggato come:

-

No - almeno ad una marca ci saranno anche dopo.

- 4226 risposte

-

- 2

-

-

- transizione ecologica

- bev

-

(e 2 altri in più)

Taggato come:

-

....piu grosso e piu luxury.

- 216 risposte

-

- 2

-

-

-

- porsche

- porsche news

-

(e 3 altri in più)

Taggato come:

-

…controdomanda…cosa vuoi discutere per due fari nuovi?? 😂

- 1866 risposte

-

- 10

-

-

![Alfa Romeo Hug [Trolling Mode]](https://www.autopareri.com/uploads/reactions/Alfaromeocare.png.50be1dd8d7c15ba4fec8098a15bfa18a.png)

-

- alfa romeo

- alfa romeo spy

- (e 11 altri in più)

-

...forse non brutto ma piu piccolo. CLE suona piu grande e cosi permette anche prezzi piu grandi 😊

-

Si certo, sono due cose diverse. Ma un auto in primis come ogni prodotto industriale piu che altro deve vendere e creare utili. Se un bel disegno aiuta di vendere piu poi un buon disegno e un vantaggio, ma quando un prodotto con bel disegno non vende, poi anche il bel disegno e senza valore. Il compito non e di creare un opera d'arte ma un prodotto che comprano i clienti piu possibile per ottimizzare il guadagno.

-

...forse un po' meno epocale se prendi solo le versione berlina, ma resta un flop per Europa, questa e sicuro

-

ET7 e gia arrivata in Europa, e in vendita a Norvegia. Gli ordini per ES8 a Norvegia sono aperto da qualche settimane e per autunno e pianificato la partenza di NIO in Germania. Apre il primo "Nio-House" settembre/ottobre a Monaco, anche per Germania e previsto la vendita di ET7 e ES8, per ET5 al momento non si sa. Dopo Germania altri paesi, si parla di Olanda, UK e forse Francia sono previsti. In parllelo con la partenza delle vendite ci sono anche piani per una rete di ricarica di alta potenza in stile Tesla SC e anche il concetto delle swaping stations per le batterie (in Cina ha molto successo) e previsto per EU, prima stazione anche a/vicino Monaco.