-

Numero contenuti pubblicati

13028 -

Iscritto il

-

Ultima visita

-

Giorni Massima Popolarità

57

Tipo di contenuto

Forum

Galleria

Calendario

Download

Articoli del sito

Store

Blog

Tutti i contenuti di 4200blu

-

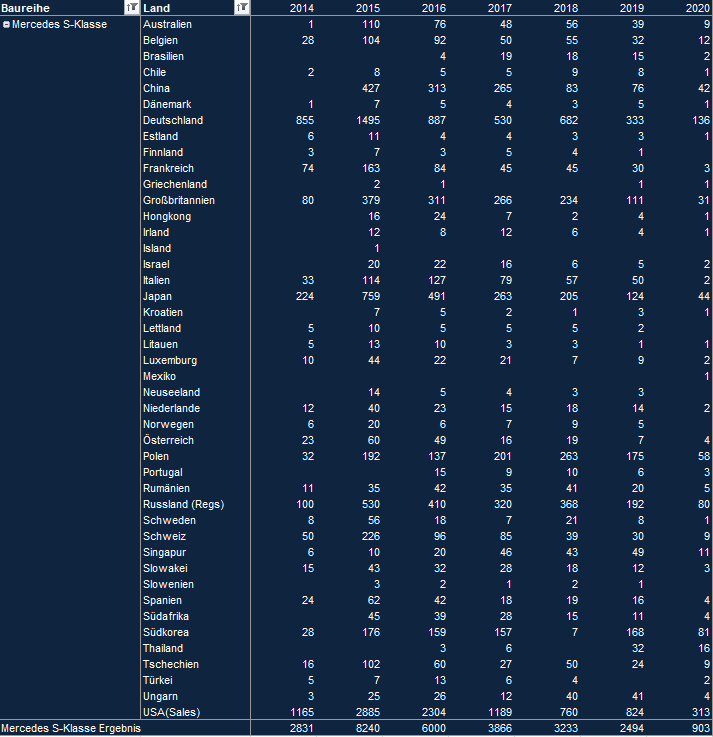

Questa e semplicimente una G70 con propulsore Bev, non sara un modello separato per la 7er come fa Mercedes con S-Klasse e EQS.

-

Si, ma per le prime consegne delle macchine sembra che sara diversa, VW ancora quest'anno (almeno in teoria se non hanno i stessi problemi come con Golf8 e ID3), invece la Skoda prossimo anno.

- 149 risposte

-

- 2

-

-

- volkswagen

- volkswagen ufficiale

- (e 7 altri in più)

-

Si, ma purtroppo non compra piu nessuno, i Coupe in genere tutto il mondo (eccetto come qualche ultimi dinosauri come me) non voglia piu 😡

- 57 risposte

-

- 2

-

-

- mercedes-benz s580

- classe s 2021

- (e 10 altri in più)

-

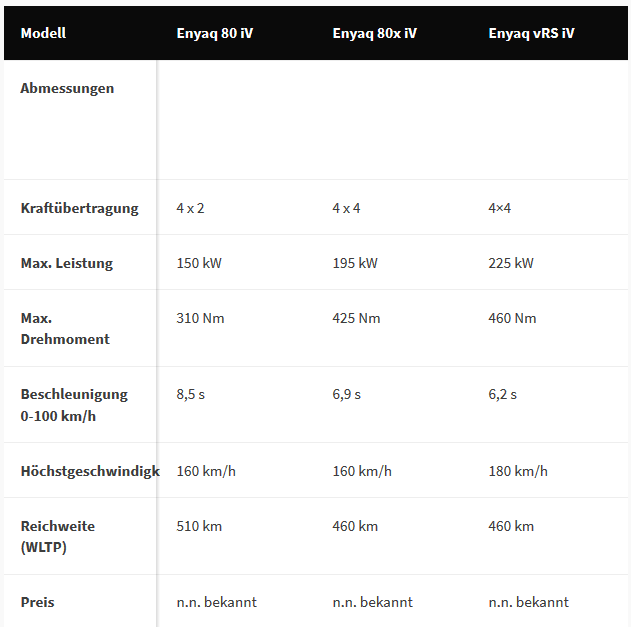

Sempre allestimento base, i differenti livelli (Loft, Lodge, Lounge ecc.) prezzo/contenuti aggiuntivi ed i prezzi per le optional trovi qui: https://www.skoda-media.de/model/105/2736?fz=105&skoda=ENYAQ iV

- 70 risposte

-

- 1

-

-

- škoda enyaq iv

- meb

- (e 9 altri in più)

-

- 70 risposte

-

- 1

-

-

- škoda enyaq iv

- meb

- (e 9 altri in più)

-

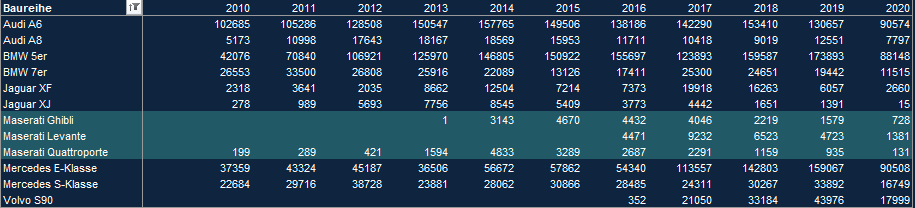

non si puo dire cosi globale. Se prendi il mercato cinese, molte berline sono costante, la Volva ha conquistato molti clienti nuovi e le Maserati dopo 3 o 4 anni crollano tutti, uguale se sono berline o Suv. Se una azienda non mantiene le prodotti non attuali, poi il mercato punisce questo, indipendente della categoria della vettura.

- 654 risposte

-

- 5

-

-

-

- ghibli trofeo

- ghibli v8

- (e 18 altri in più)

-

Head up display con augmented reality

- 57 risposte

-

- 1

-

-

- mercedes-benz s580

- classe s 2021

- (e 10 altri in più)

-

..anche se secondo me il problema principale non e il cruscotto per se ma questi due tablet terribilmente inguardabile 🤮 Fuori invece trovo bellissima, complimenti ai designer!

- 57 risposte

-

- 4

-

-

-

-

- mercedes-benz s580

- classe s 2021

- (e 10 altri in più)

-

Per la nuova S-Klasse anche una nuova fabbrica Maximum flexibility thanks to the assembly system of the future in Factory 56: Mercedes-Benz has made its production more flexible Flexible, digital, efficient and sustainable: Factory 56 embodies the future of production at Mercedes-Benz and sets new standards for the automotive industry. With an investment of approximately 730 million Euros, the factory at the Mercedes-Benz plant in Sindelfingen is a clear commitment to Germany as a business location. In total, Mercedes-Benz is investing about 2.1 billion euros at the Sindelfingen site. At the same time, the company is increasing efficiency in Factory 56 by 25 percent compared to the previous S-Class assembly. Production in Factory 56 is characterized by maximum flexibility; this applies to the number of models produced and the production volume as well as to material flows. New models – from compact cars to SUVs, from conventional to plug-in hybrid to electric drive – can be integrated into series production in just a few days. Production can be adjusted quickly and flexibly to meet market demand. In line with Ambition 2039, Factory 56 will be a zero-carbon factory – completely CO2-neutral and with significantly reduced energy requirements. This is made possible, among other things, by its innovative energy concept with a photovoltaic system, a DC power grid and energy storage systems based on reused vehicle batteries. Innovative technologies and processes have been implemented consistently and comprehensively throughout the assembly hall, providing the best possible support for the employees in their daily work. The concept of Factory 56 will be gradually transferred to all Mercedes-Benz car plants around the world as a blueprint. In Factory 56, everything is about maximum flexibility: Production is rapidly adapted in an uncomplicated manner depending on market demand. New models and derivatives can be integrated into processes and production capacities can be shifted between the plants. Production also excels with maximum flexibility on the assembly line: Electric vehicles from the EQ product and technology brand are integrated into series production. Thanks to highly flexible structures, Mercedes-Benz produces vehicles with different drive systems on one line, enabling it to respond flexibly and rapidly to changes in demand. Factory 56 is the best example. This is where large numbers of very different vehicles with new drive technologies and vehicle architectures are produced in the top quality for which Mercedes-Benz is known. Initially, the new generation of the Mercedes-Benz S-Class sedan and its long-wheelbase version will leave the production line of Factory 56. Later on, the Mercedes-Maybach S-Class and the EQS, the first all-electric member of the new S-Class family, will be produced on the same line with full flexibility. The assembly hall is 100 percent flexible, so that all Mercedes-Benz model series can be integrated into ongoing production in the shortest possible time, depending on demand – from compact vehicles to SUVs. One of the major success criteria of Factory 56 is therefore its maximum flexibility in terms of the number of models produced, production volume and material flows. Production is rapidly adapted in an uncomplicated manner, depending on market demand. New models and derivatives, such as successor model series, can be integrated into series production within a matter of days. TecLines and modular marriage Among other things, this is made possible by the assembly system of the future, which is employed in Factory 56 and gives the entire production a more flexible structure. Two so-called TecLines serve to avoid fixed points in the assembly process, improving the flexibility of the entire factory. They are located at the start of interior fitting, and bring together all the complex plant technologies at one point. This means that conversion work necessitated by the integration of new models, for example, is easier to carry out in the other areas of the assembly hall. In the TecLines, the traditional production line is replaced by automated guided vehicles, allowing the best possible changeover between continuous and cycled operation. This is appropriate for automated activities such as the installation of the aluminum roof. To integrate a new product and incorporate any associated new technical equipment, it is only necessary to change the route of the AGVs. A total of more than 400 AGVs are in operation in Factory 56. Alongside the TecLines, they supply the employees on the line with shopping carts especially pre-picked for the vehicle concerned. In addition, the so-called “Fullflex Marriage” sets a new standard for the process whereby the vehicle body is connected to the drive system. In Factory 56, this “marriage” consists of several modular stations. For new product requirements, the individual modules can be replaced within one weekend. This allows major conversion work and longer interruptions in production to be avoided. New shopping cart concept To produce a wide range of models on a single line, conventional production requires a lot of space to store different parts directly at the assembly line. In Factory 56, the parts to be installed are no longer stored at the line, but in so-called picking zones in the center of the assembly hall, where they are selected on a vehicle-specific basis. AGVs bring the required parts directly to the installation point in specifically pre-commissioned shopping carts. Thanks to the conveyor technology, up to four shopping carts per vehicle can be transported per vehicle. This organization of the parts supply to the line allows an efficient assembly process while ensuring that the correct parts are installed in each vehicle. With Factory 56, Mercedes-Benz is taking another important step towards the workplace of the future. The entire concept of the new assembly hall places the employees even more at the center of things. Following the successful start, the more than 1500 employees of Factory 56 will work in two shifts, at ergonomically optimized, height-adjustable stations where they are given the best possible support in their activities by digital tools. A further development of the working organization and flexible working-time models were developed together with the Works Council, in order to support the employees in their desire for a positive work-life balance. The goal is for the employees to enjoy coming to their workplace – whether to the office or the production line. Wherever possible, Mercedes-Benz took the employees’ wishes into account from the start when planning Factory 56. For example, production employees were able to state in an online survey on their personal preferences in which shift, in which area and with which colleagues they would like to work. The employee response rate was very high, and more than 85% of the wishes expressed were granted. Flexible working time models for better compatibility of family and working life The working-time models in Factory 56 place people at the center of things. For many years, the company has offered its employees a variety of working-time models, and with this extended option it meets the growing desire of its employees for even more freedom of personal action by virtue of more flexible and more rapidly agreed working times and locations. To meet these wishes, Factory 56 has a model for flexible personnel deployment, known as the personnel pool, to relieve the regular workforce. In this way, the employees’ needs can be better taken into account according to a work plan as their personal situation requires, thereby improving compatibility between family and working life. Factory 56 implements the Mercedes-Benz YES initiative, which was already set up in 2015. “YES” stands for “Young, Experienced = Successful,” and aims to initiate a cross-generational dialog in production. The idea is for young and experienced colleagues to work hand in hand so that they benefit from each other. Ergonomically optimal workplaces Ergonomics are a particularly important factor in Factory 56 and the individual stages of assembly were examined with respect to ergonomic requirements at an early stage. For example, a virtual assembly station was used for experienced employees to test different assembly activities in advance using virtual reality, so that adjustments could be made to the planning and design of production if necessary. The vehicles on the line can be brought into ergonomic, less stressful working positions using selected conveyor techniques such as overhead rotating conveyors or mobile platforms. The height of the vehicles can be adjusted at every station. The working day is also made easier by ultra-modern digital systems and equipment. In the paperless factory, the employees work with tools such as monitors and PDAs. Thanks to a digital positioning system, bolting tools are precisely programmed for the work needed on the relevant vehicle. In this way, only the tools actually required for working on the vehicle are activated. Plenty of daylight for a pleasant working environment Modern working environments are reflected in both the production environment and office areas. The assembly hall is designed to let a lot of light in. Its blue-sky architecture with windows in the roof makes use of daylight to promote a pleasant working climate for the employees. The break areas in the building are designed to the latest standards with friendly colors and high-quality materials, creating a pleasant atmosphere for the employees. This is also helped by sofas and spacious kitchen units. The factory also has its own canteen so that staff can avoid having to walk long distances on the site.

-

Digital light - una delle innovazione per la S-Klasse https://api.media.mercedes-benz.com/v2/storage/v1/public/236d8bcc-ab49-4447-8ef2-f0b3d8d39009/1.8.mp4/20200826-8-digital-light-trailer.mp4

-

- 70 risposte

-

- škoda enyaq iv

- meb

- (e 9 altri in più)

-

- 70 risposte

-

- škoda enyaq iv

- meb

- (e 9 altri in più)

-

Versione base Enyaq 50 iV con motore base 109Kw WLTP 340Km autonomia) costa in Germania 33.800.-€ (prima incentivi).

- 70 risposte

-

- 2

-

-

-

- škoda enyaq iv

- meb

- (e 9 altri in più)

-

una traccia non cosi male....😎 https://www.autoblog.com/2020/05/23/bmw-x8-m-rumors/

-

Naturalmente noi comuni mortali siamo lontano di sapere cosa voglia uno come Wolff, ma mi posso imaginarmi, che lui e molto di piu imprenditore e investore (un settore dove ha lavorato prima e anche adesso con i suoi partecipazione alla Scuderia Mercedes e Williams e con la partecipazione alla Aston Martin). Non sono sicuro che uno come lui pretendera un job come funzionario alla FIA (come Todt).

-

per le vendite dopo 5-7 anni sicuramente piu la forma.

- 654 risposte

-

- 5

-

-

- ghibli trofeo

- ghibli v8

- (e 18 altri in più)

-

- 38 risposte

-

- rolls-royce ghost

- ghost 2021

- (e 5 altri in più)

-

..se non sarebbe stato il periodo Todt/Brawn poi la Ferrari sarebbe piu o meno senza successo da ca. 40 anni.

-

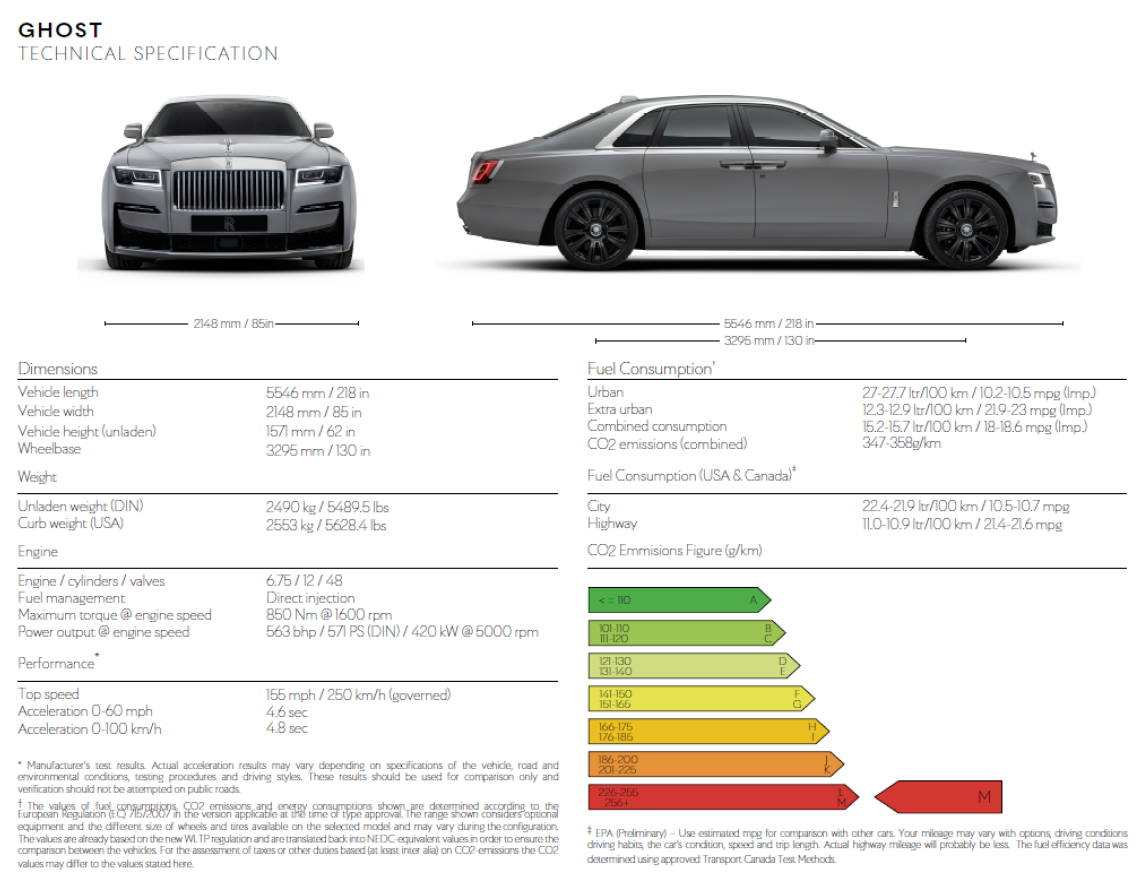

ci sara anche la R22 (Ghost EWB) con la porta piu lunga.

- 38 risposte

-

- rolls-royce ghost

- ghost 2021

- (e 5 altri in più)

-

..al momento nel documento ufficiale parlano solo di due altri benzina e 2 diesel che saranno introdotto verso fine anno senza specificazione piu dettagliata....

- 37 risposte

-

- 31 risposte

-

- rolls royce

- ghost

-

(e 4 altri in più)

Taggato come:

-

fixed 😂

-

...sarebbe lo stesso livello come R8 V10performance o Roma - mi sembra un po' alto per una Maserati (almeno se non limiterano le uniti prodotti, con 500 uniti sarebbe un altra discussione)

- 1687 risposte

-

- 1687 risposte