-

Numero contenuti pubblicati

13034 -

Iscritto il

-

Ultima visita

-

Giorni Massima Popolarità

57

Tipo di contenuto

Forum

Galleria

Calendario

Download

Articoli del sito

Store

Blog

Tutti i contenuti di 4200blu

-

Gia questi completamenti assurdi per un uso stradale. Gia con le bev "normali" con potenze elevante la maggior parte dei utenti e sovracarica. Studia/pubblicazione di una dei piu grandi assicurazioni (AXA) --> le bev hanno molto piu incidente con dani molto piu gravi, segno forte che la gente non sono capace di gestire questi potenze elevate.

- 2081 risposte

-

- 1

-

-

- cabriolet

- maserati spy

-

(e 4 altri in più)

Taggato come:

-

- 2081 risposte

-

- cabriolet

- maserati spy

-

(e 4 altri in più)

Taggato come:

-

Cambiera Tesla da IDRA a Bühler per le Giga-Press? Tesla Reportedly Looking To Change Giga Press Suppliers The automaker is said to be in talks with Switzerland’s Bühler, according to industry watcher. Tesla has so far had only one supplier for its Giga presses, Italy’s IDRA, but according to information from China, starting next year it will switch to a new manufacturer. Take this with a grain of salt for now as it is only a rumor, and even if true, it doesn’t necessarily mean IDRA will be dropped altogether - maybe the two companies will build different machines. Bühler was actually approached by Tesla back in 2019 when the automaker had announced that it was looking for a 6,000-ton Giga press. The Swiss multinational plant equipment manufacturer turned down the offer then, but the fact that Bühler was considered three years ago does confirm that the two companies are in contact. Tesla’s Giga press supplier will be replaced from Italy’s IDRA to Switzerland’s Bühler next year. The latter is also one of the world’s 6 largest die-casting giants. It rejected Tesla’s demand for a 6000t-level Giga press in 2019, but now their products offer better performance. Tesla’s Giga press supplier will be replaced from Italy’s IDRA to Switzerland’s Bühler next year. The latter is also one of the world’s 6 largest die-casting giants. It rejected Tesla’s demand for a 6000t-level Giga press in 2019, but now their products offer better performance. Tesla is said to have at least 12 Giga presses today and it will need more of them as it continues looks to start building all its vehicles from fewer (and larger) cast pieces. The manufacturer has currently only used mega castings in the production Model Ys built at its Austin and Berlin plants; it takes under two minutes for each large casting to be created, so double that and that’s how long it takes Tesla to create a new Model Y shell. (insideev)

-

Si, ma le Mxx sono M-Sport, invece la XM sara in vendita come Full-M come M3 o M5.

-

..piu...

-

La M non ha mai usato motori diesel 😂, perche dovrebbe cambiare adesso in un era dove il diesel morira?

-

XM sara sempre Phev in tutte variante.

-

...come gia dice il nome XM tutti variante sono M 😉..e ci saranno anche nelle mercati europei tutte variante disponibile.

-

Non sono sicuro se prendono qualcosa gia pronta del partner, BMW ha l'intenzione nel CMCC a Parsdorf di sviluppare la costruzione delle cellule future lo stesso e il fornitore fa solo la produzione..un po' come il sistema Apple con Foxconn e altri. Ma naturalmente non e certo, che questo piano funzionera.

- 256 risposte

-

- rolls-royce

- scelte strategiche

-

(e 2 altri in più)

Taggato come:

-

BMW Group commences in-house production of fuel cells for BMW iX5 Hydrogen in Munich. Hydrogen is an additional option for electric drive systems +++ Fuel cells are manufactured in the company’s competence centre for hydrogen +++ BMW Group leads the way in hydrogen technology in the premium electric vehicle segment Munich. On 31 August, Chairman of the Board of Management of BMW AG Oliver Zipse and Frank Weber, Member of the Board of Management of BMW AG responsible for Development, will come together to inaugurate fuel cell system production at the company’s competence centre for #hydrogen in Munich. The reason for this occasion is the small series of #BMW iX5 Hydrogen cars that will be entering service around the world from the end of this year for test and demonstration purposes. The combination of #fuel cell and high-performance #battery is set to enrich the company’s portfolio by adding a unique form of drive system for the premium segment. The BMW Group is playing a visionary and pioneering role in this technology with the aim of achieving a more diversified transition to #zero-emission mobility. “As a versatile energy source, hydrogen has a key role to play on the road to climate neutrality. And it will also gain substantially in importance as far as personal mobility is concerned. We think #hydrogen-powered vehicles are ideally placed technologically to fit alongside battery-electric vehicles and complete the electric mobility picture,” said Oliver Zipse, Chairman of the Board of Management of BMW AG, in Munich on Wednesday. “By commencing small-scale production of fuel cells today, we are demonstrating the technical maturity of this type of drive system and underscoring its potential for the future.” “Our many years of research and development work have enabled us to get the very most out of hydrogen technology,” added Frank Weber, Member of the Board of Management of BMW AG, Development. “We have managed to more than double the fuel cell’s continuous output in the second-generation fuel cell in the #BMW iX5 Hydrogen, while weight and size have both decreased drastically.” Thanks to these advances, the BMW Group leads the way in the development of #hydrogen technology and considers it to hold great promise for its next generation of vehicles. Technological expertise and high standards of efficiency in the drive system The BMW Group will now be manufacturing highly efficient fuel #cell systems at its in-house competence centre for #hydrogen. This technology is one of the core elements in the BMW iX5 Hydrogen and generates a high continuous output of 125 kW/170 hp. It teams up with an electric motor featuring fifth-generation BMW eDrive technology and a high-performance battery purpose developed for this vehicle to enable its powertrain to deliver 275 kW/374 hp. The development team incorporated the powerful drive system – comprising two hydrogen tanks, the fuel cell and the electric motor – into the existing #BMW X5 platform for the small production run. The BMW iX5 Hydrogen already successfully demonstrated its excellent everyday usability, even at very low temperatures, during the final round of winter testing in Sweden at the start of this year. The impressive testing results of this new small-scale series of cars are rooted in the BMW Group’s extensive experience with the use of hydrogen as a drive technology. Hydrogen-powered combustion engines had already been in use prior to the arrival of the fuel cell system. Efficiency considerations prompted the BMW Group to continue development work in this area from 2015 with the BMW 5 Series GT Hydrogen Cell based on fuel cell technology. Fuel cell technology has since been steadily refined by harnessing the company’s vast know-how in the field of conventional drive technologies and applying the exacting standards of all-round efficiency it expects of all its vehicles. Production of fuel cell systems in Munich A chemical reaction takes place in the fuel cell between hydrogen from the tanks and oxygen from the air. Maintaining a steady supply of both elements to the fuel cell’s membrane is of crucial importance for the drive system’s efficiency. In addition to the technological equivalents of features found on combustion engines, such as charge air coolers, air filters, control units and sensors, the BMW Group also developed special hydrogen components for its new fuel cell system. These include the high-speed compressor with turbine and high-voltage coolant pump, for instance. The BMW Group sources the individual fuel cells required for manufacturing the BMW iX5 Hydrogen from the Toyota Motor Corporation. The two companies have enjoyed a partnership characterised by trust for many years and have been collaborating on fuel cell drive systems since 2013. Fuel cell systems are manufactured in two main steps. The individual fuel cells are first assembled into a fuel cell stack. The next step involves fitting all the other components to produce a complete fuel cell system. Stacking of the fuel cells is a fully automated process. Once the individual components have been inspected for any damage, the stack is compressed by machine with a force of five tonnes and placed in a housing. The stack housing is manufactured in the light metal foundry at BMW Group Plant Landshut using a sand casting technique. For this, molten aluminium is poured into a mould made from compacted sand mixed with resin in a process specially designed for this small-series vehicle. The pressure plate, which delivers hydrogen and oxygen to the fuel cell stack, is made from cast plastic parts and light-alloy castings, also from the Landshut plant. The pressure plate forms a gas-tight and water-tight seal around the stack housing. Final assembly of the #fuel cell stacks includes a voltage test along with extensive testing of the chemical reaction within the cells. Finally, all the different components are fitted together in the assembly area to produce the complete system. During this system assembly stage, further components are fitted, such as the compressor, the anode and cathode, the high-voltage coolant pump and the wiring harness. (BMW Group)

- 256 risposte

-

- 1

-

-

- rolls-royce

- scelte strategiche

-

(e 2 altri in più)

Taggato come:

-

VW Group to trim executive board, report says VW brand's procurement boss and the group's sales boss will lose their board seats under a reshuffle planned by new CEO Oliver Blume. HAMBURG -- Volkswagen Group's supervisory board agreed on Tuesday evening to remove two seats from the automaker's 12-person management board, sources familiar with the matter said. The news comes as Porsche CEO Oliver Blume takes over as VW Group CEO from Herbert Diess on Sept. 1. The move signals a sharper focus under Blume's leadership following Diess' turbulent four-year tenure that saw the board swell to its current level. VW's supervisory board discussed the move in a meeting on Tuesday evening but must still confirm a final decision in writing, the sources said. VW declined to comment. VW brand's procurement boss Murat Aksel and group sales boss Hildegard Wortmann will lose their board seats under the reshuffle, German media reports said. Other management board members such as Audi CEO Markus Duesmann, VW brand CEO Thomas Schaefer and technology chief Thomas Schmall will keep their board seats, the reports said. The appointment of the 54-year-old Blume as VW Group CEO reflects efforts by the automaker's controlling shareholder families to keep the group on a shorter leash and have greater say over strategy, sources have told Reuters. Preliminary steps to list VW Group's Porsche brand on the stock market, a move which would further solidify the families' control, are expected in coming days, according to sources familiar with the matter, triggering an announcement of an initial public offering as soon as the first week of September. (Reuters)

- 1073 risposte

-

- italdesign

- jetta

-

(e 15 altri in più)

Taggato come:

-

-

...come hanno gia scritto parecchie prima, premium non e una questione dalla meccanica, una Mercedes /8 nel epoca era tutt' altro come brilliante, assetto pericoloso, motore debolissimo, sterzo come un camion...ma tuttavia era gia premium, anche se questo termine nelle anni sessante non era inventato.

-

EV brand Zeekr becomes first to adopt CATL’s 1,000km Qilin battery Geely-owned electric car brand Zeekr says it has become the first marque to commit to using a 1,000km range battery made by Chinese Amperex Technology Limited (CATL). The 1,000km range battery, dubbed Qilin, uses a cell-to-pack format that CATL – which also supplies batteries to Tesla – says has an energy density of 255Wh/kg, and a “record-breaking” volume utilisation efficiency of 72%. While the energy density is not quite that of Tesla’s 4680 batteries (expected to deliver around 260Wh/kg according to Enpower), the Qilin battery is also expected to offer hot starts in five minutes, fast-charging in ten minutes, and thermal stability that promises to increase the life and safety of the battery. The volume utilisation is also a big jump up from CATL’s first cell-to-pack battery in 2019, which scored a 50% utilisation efficiency rate. The new announcement from Zeekr and CATL forms part of a five year strategic cooperation agreement that will see the battery maker provide Qilin batteries at volume to the brand. The first Zeekr EV to be fitted with the Qilin battery will be the upcoming 009, an all-electric luxury people mover with an imposing presence on the road that is underlined by its Rolls-Royce inspired “grille.” Now, it would appear this could be considerably more, assuming the 1,000km range in fact refers to real world range. However this is unclear, and since China’s CLTC ratings are somewhat similar to NEDC, it may mean the actual range of the 009 is closer to the 700km figure. In the second quarter of 2023, the 001 – which rolled off the factory floor for the first time in production-ready format in October 2021 – will also be available with a Qilin battery inside, and known as the “001 Qilin edition.” It is available in a single 200kW/384Nm motor variant with 100kWh battery, as well as two dual-motor variants both deliver 400kW power output and 768Nm torque with either a 86kWh or 100kWh battery. While the single-motor variants gets the longest range it is limited to 100km/hr in 6.9 seconds. By contrast, both dual motor variants can complete the 100km/hr sprint in 3.8 seconds. The Qilin battery differs from CATL’s M3P battery that it is rumoured Tesla will substitute into the Shanghai-made Model Y in the fourth quarter of 2022 – and which it has been reported may be just that – a rumour. (thedriven)

-

..che non va in serie cosi (con questa materiale)...

- 46 risposte

-

- mini

- mini aceman concept

-

(e 4 altri in più)

Taggato come:

-

….solo che costa 30% meno..

-

...fatto valido per ognuno bev al momento....

-

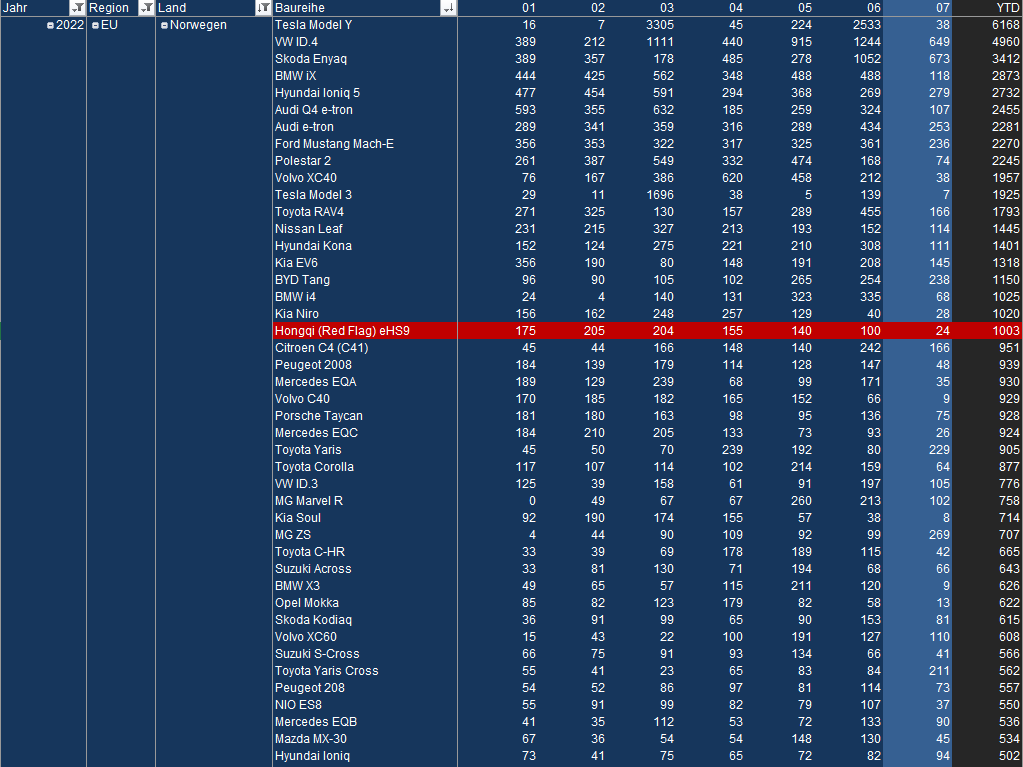

Anche FAW con il brand Hongqi attacca i Europa, primo mercato con primo modello sara Olanda con la suv E-HS9. Prime consegne sono pianificato per fine 2022. E gia in vendita a Norvegia ad un prezzo di ca. 62.000.-€

-

Al momento non si sa molti dettagli, solo che BYD collabora con la Hedin Group, un dei dealer piu grande d'Europa (125.000 vetture vendute in 2021, 260 posti di vendita, 6300 impiegati in 8 paesi europei). Hedin deve aprire in tutte le grande citta di Germania un punto di vendita, il primo dovrebbe aprire da ottobre, la citta al momento non e pubblicato.

- 147 risposte

-

- 3

-

-

..dipende sicuramente dal mercato (situazione a mercato casa forse meglio), ma provi qui in Germania per una Fiat/Alfa o una Hyundai di trovare un pezzo di ricambio original entro 3 ore..impossibile, in Mercedes o BMW possibile, oppure provi d fare un tagliando "overnight", anche impossibile per un genralista, per un premium invece possibile.