Tutti i contenuti di 4200blu

- Fiat -> FCA -> Stellantis - Filosofia su una holding multinazionale

- Fiat -> FCA -> Stellantis - Filosofia su una holding multinazionale

-

Audi RS 5 & RS 5 Avant 2026

Hai centrato quasi perfettamente il punto…... Nell'Audi, il motore nell'asse posteriore è responsabile per il active torque vectoring.

- Fiat -> FCA -> Stellantis - Filosofia su una holding multinazionale

-

Audi RS 5 & RS 5 Avant 2026

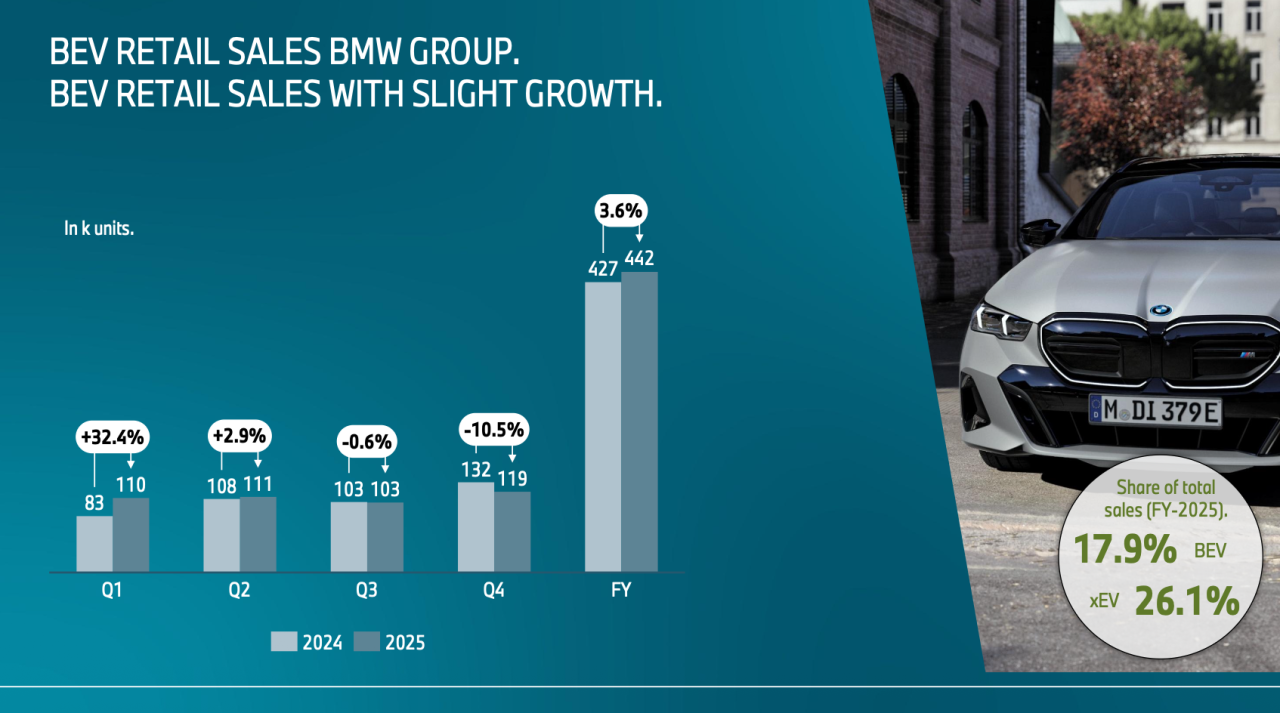

Ma non è proprio questo il piano: rendere i motori/versioni a combustione sempre meno attraenti, fino a quando i clienti non si rassegneranno e passeranno volontariamente all'elettrico, raggiungendo così l'obiettivo prefissato?

-

Audi RS 5 & RS 5 Avant 2026

2370kg…..non così lontano dalla M5…. 😜

- Ferrari Luce 2026 - Prj. F244 (Spy)

-

Horse Powertrain e Repsol Horse H12 Concept

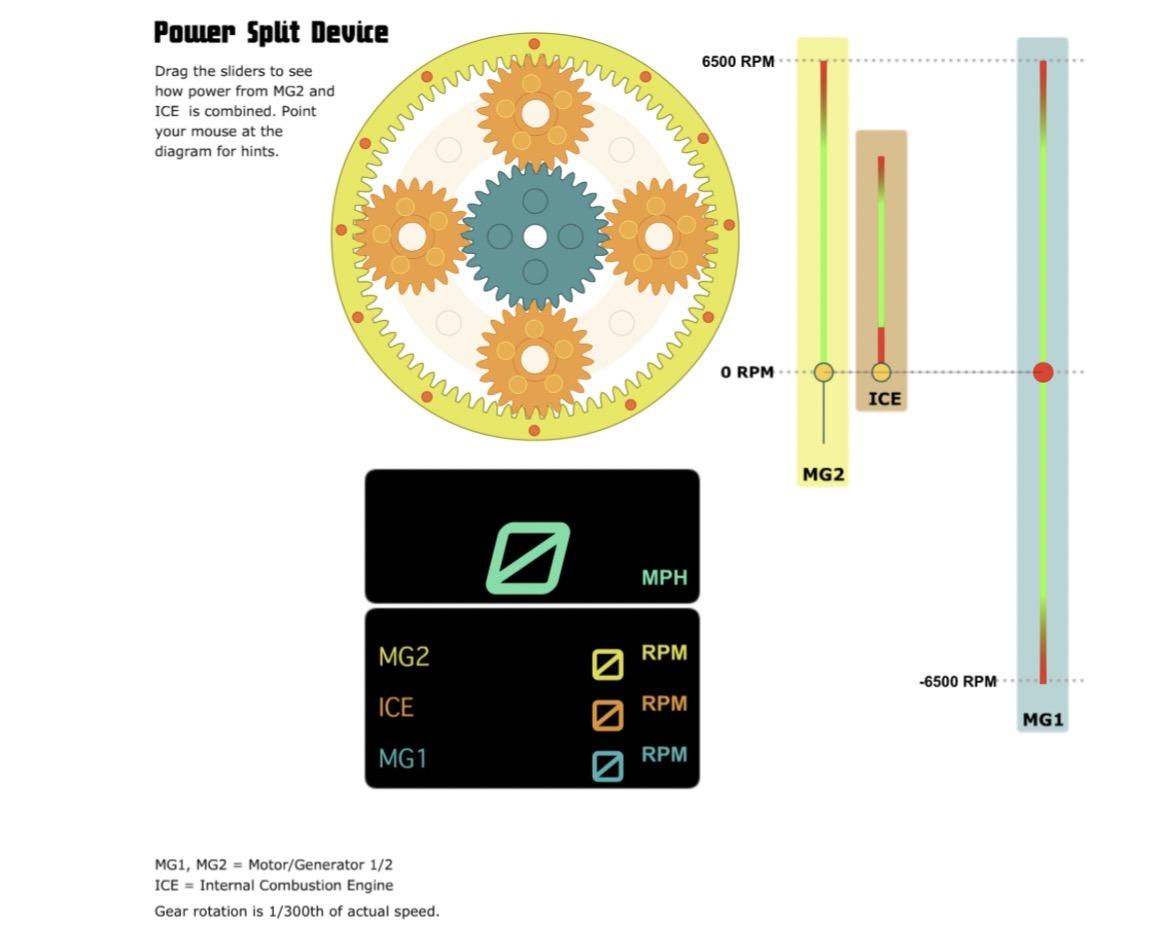

Toyota Prius - Power Split Device (PSD)The Toyota Prius is packed with some pretty high-tech stuff, but at the heart of the Hybrid Synergy Drive (HSD) is a simple little device called the Power Split Device, or PSD. The PSD is a planetary gear set that removes the need for a traditional stepped gearbox and transmission components, and also the familiar rev-lurch-rev-lurch of acceleration in an ordinary gas powered car. It acts as a continuously variable transmission (CVT) but with a fixed gear ratio. If you have no mathematical or mechanical understanding of hybrid technology or even regular engine components, this will help you get a feel for how the PSD allows the car to use power from an internal combustion engine (ICE), as well as 2 electric Motor/Generators (MG1 and MG2), all spinning at different and variable speeds. The PSD even allows the smaller of the two Motor/Generators, MG1, to act as a starter for the ICE, thereby eliminating another component of a traditional gasoline engine. The model below allows you vary the speed of both the ICE, and MG2. MG2 is the larger of the 2 electric motor/generators and is also referred to as the traction motor because its speed (RPM, or revolutions per minute) has a fixed relationship to the speed of the wheels. Dragging the MG2 slider, you'll see that the speedometer changes, while changing the speed of the ICE does not directly affect speed. Once you master that concept you'll start to see how the CVT function works. The ICE can spin faster or slower, depending on how much power is needed, and with either resistance or assistance from the electric motors the car can reach the desired speed while always keeping the ICE running at the most efficient rate possible. Rotation speeds of MG1, MG2, and ICE are inter-dependent, and the speed of MG1 will always change when you vary the speed of either of the other 2. MG1 has a maximum rate of 10,000rpm in either direction (positive or negative) with a software limit of 6500 RPM if ICE is off. Using the model below, you can see for yourself why this software limit means the ICE will always spin if you're travelling above 42mph. And in case you were curious, yes MG1 can and often does change spin directions under normal driving conditions. ICE rotation is limited to speeds between 1000rpm and 4500rpm. It can also stop completely, but anything between 0 and 1000 will force the slider up or down. That's because the internal combustion engine can't operate effectively below that speed. The hybrid computer knows, and will stop the ICE when it decides you don't need to use any gas, and start it again when you need more power, or higher speed from MG1.

- Audi RS5 & RS5 Avant 2026 - Prj. B10 (Leak)

- Audi RS5 & RS5 Avant 2026 - Prj. B10 (Leak)

- Audi RS5 & RS5 Avant 2026 - Prj. B10 (Leak)

-

Horse Powertrain e Repsol Horse H12 Concept

E dove saltano fuori le quantità necessarie di questi carburanti renewwable? Dove sono gli ingenti investimenti necessari nelle infrastrutture per rendere questa tecnologia una realtà su larga scala? Bello un propulsore cosi, ma senza il volume sul mercato dei carburanti non serve molto.

-

Scelte strategiche gruppo VAG

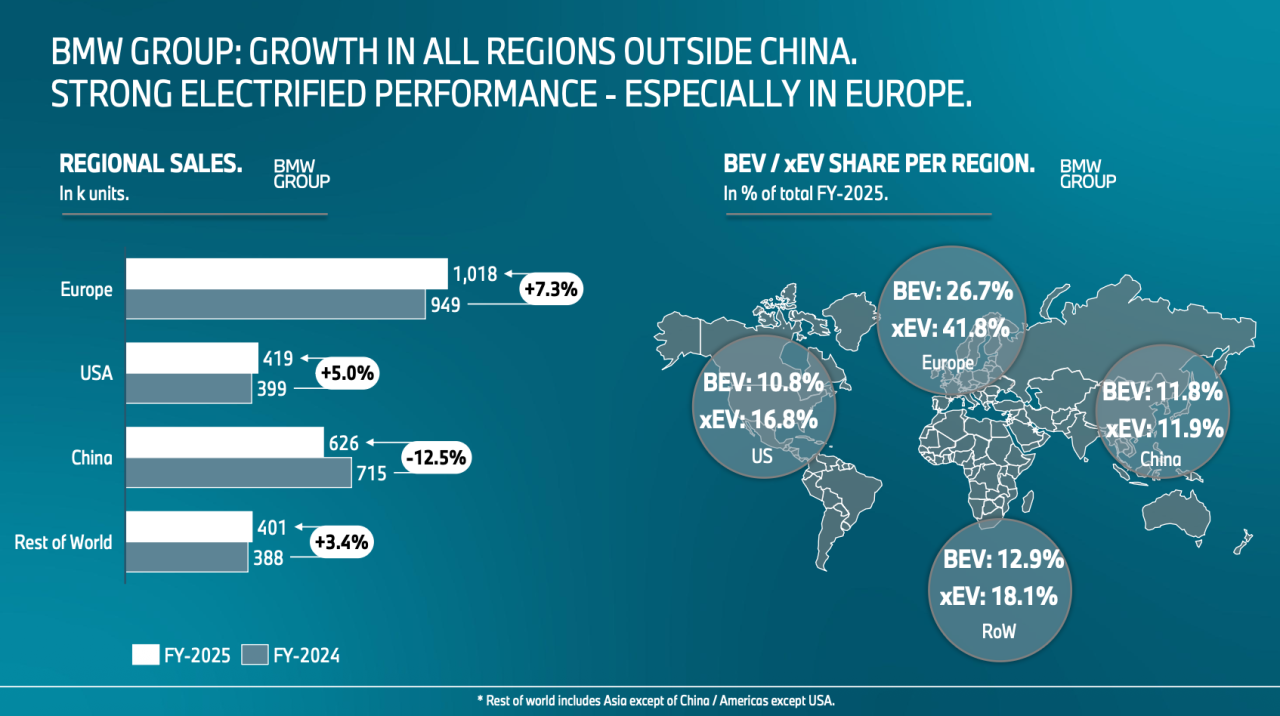

Errore di ragionamento: se tutto intorno crolla, anche BMW non potrà più reggere, quindi forse saranno loro a spegnere la luce.

- 1578 risposte

-

-

- 2

-

-

- audi

- cupra

- ducati

- lamborghini

-

Taggato come:

-

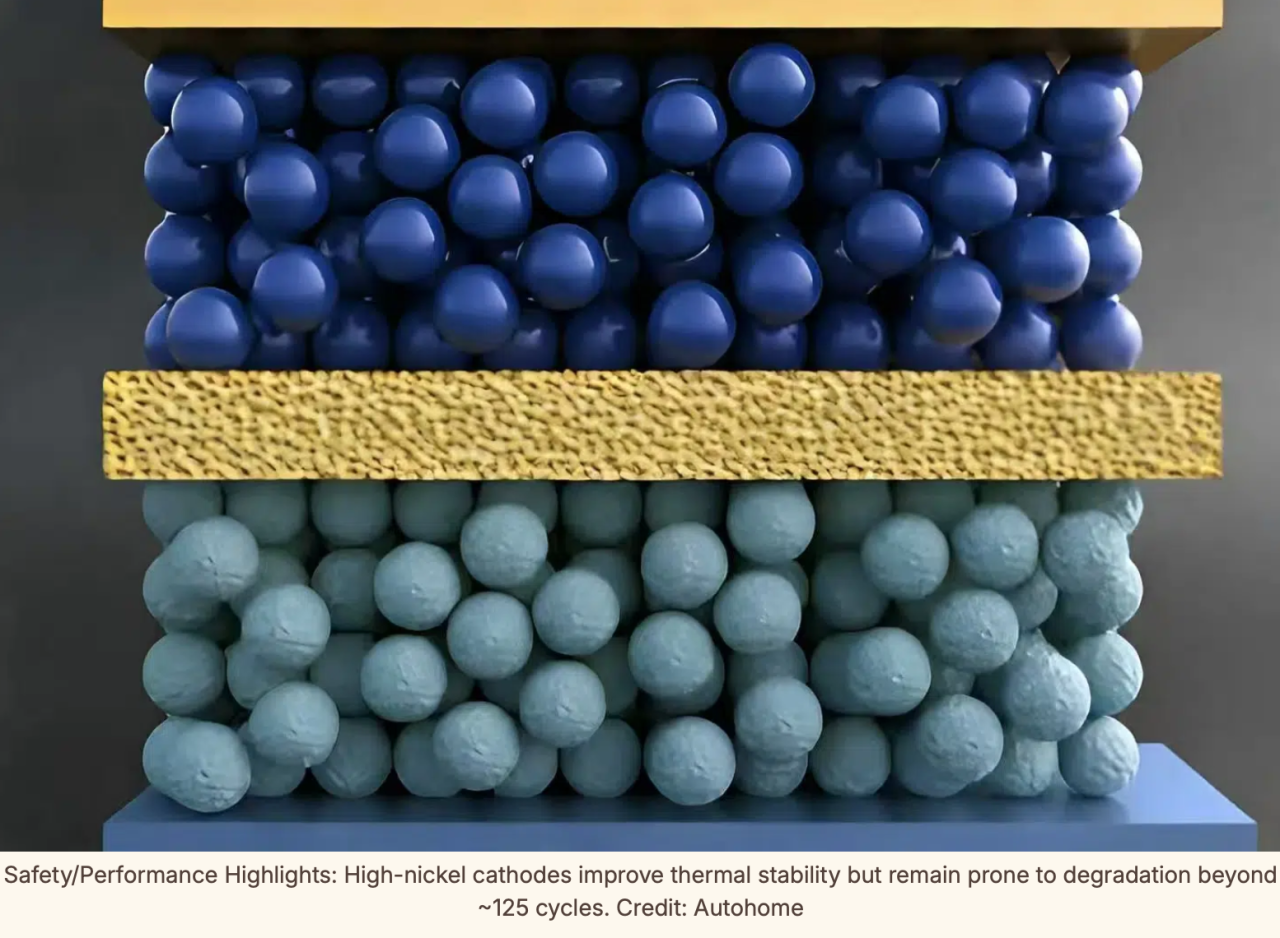

Novità Batterie Stato Solido e Semi-solido

Solid-state battery breakthrough hinges on cathode innovation, not electrolytesThe third China solid-state battery innovation summit in Beijing, earlier this month, highlighted industry-wide challenges, with Professor Xia Dingguo of Peking University noting that energy density, primarily determined by the cathode, remains critical, and that cathode innovation, rather than electrolyte breakthroughs, is key to moving solid-state batteries from laboratories to commercial production, as Autohome reports. The resurgence of interest in solid-state batteries is linked to two main factors: substantial improvements in overall research capabilities since the 1990s, and the growing demand for higher energy density, safety, and material optimisation in EV applications. Solid-state batteries are expected to achieve high energy density, safety, long life, and low cost, but without breakthroughs in cathode technology, their industrial significance is limited. Current challenges centre on interface stability and material compatibility. Experiments with high-nickel cathodes demonstrate improved thermal stability but retain safety risks under high current or voltage conditions due to local polarisation, formation of a high-impedance layer, and eventual performance degradation. Fluorine doping can temporarily stabilise cycling, but degradation accelerates beyond around 125 cycles. Crystalline cathode materials are anisotropic, and even small volume changes can concentrate stress at interfaces, limiting cycle life. Material compatibility further constrains commercial adoption. Different solid electrolytes, including chlorides, sulfides, and oxides, exhibit varying moduli and interface behaviour. Oxides are too rigid; sulfides and chlorides often require applied pressure, which complicates manufacturability. Addressing these challenges will require low-modulus, interface-friendly electrolytes or optimised polymers capable of broad voltage windows and high conductivity. China’s leading battery manufacturers, including CATL, BYD, and Eve Energy, have begun integrated development of cathode and electrolyte systems, creating patent protections while optimising cell performance. Advances in dry electrodes, co-sintering, and cold sintering are further enabling scalable production and reducing reliance on complex coating processes. Looking forward, the industry is expected to pursue diverse paths for different applications: high-end EVs with polymer electrolytes and high-nickel or lithium-rich cathodes; mass-market EVs focusing on LiFePO4 systems, emphasising safety and cost; and specialised applications exploring sulfide electrolytes paired with sulfur cathodes. The summit concluded that cathode material innovation is the “bull’s nose” of industrial solid-state batteries. Electrolytes remain important, but energy density, cost, and stability fundamentally depend on cathode development. The future will require dual-track progress in material innovation and engineering manufacturing to ensure China’s leadership in the global solid-state battery sector. (CNC)

-

Scelte strategiche gruppo VAG

Non è davvero sorprendente: la chiusura degli stabilimenti è l'unico modo per ridurre in modo permanente i costi fissi, soprattutto se non si ha bisogno della capacità produttiva e non se ne avrà mai più bisogno.

- 1578 risposte

-

-

- 2

-

-

- audi

- cupra

- ducati

- lamborghini

-

Taggato come:

-

BMW Serie 1 2024

E. come ha scritto @Felis . Per la F70 non c'è più nulla da aspettarsi ecerto un update per Euro7.

- 190 risposte

-

- bmw

- bmw serie 1

- bmw serie 1 f70

- bmw spy

-

Taggato come:

-

Avvistamenti vari di auto storiche o quasi-storiche

- Fiat -> FCA -> Stellantis - Filosofia su una holding multinazionale

- Avvistamenti auto moderne rare

- Fiat -> FCA -> Stellantis - Filosofia su una holding multinazionale

- Fiat -> FCA -> Stellantis - Filosofia su una holding multinazionale

- Lancia Ypsilon 2024

….ancora una volta vi dimenticate completamente della questione delle emissioni di CO2. Già oggi Stellantis non rispetta i valori limite fissati dall'UE, se non attraverso il pooling. Con un'auto che peggiora questo bilancio di 14g per ogni unità venduta, generando meno fatturato ma costi di pooling più elevati o addirittura sanzioni pecuniarie, dove sta il vantaggio finanziario per il produttore?- Scelte strategiche BMW Group

- Scelte strategiche BMW Group

- Renault Twingo IV E-Tech Electric 2026

Vero. In Germania, secondo una studia della piu grande assicurazione per macchine, quasi il 90% delle auto elettriche immatricolate di person private sono di proprietà di proprietari di case, quindi con la possibilita di ricaricare nella proria garage. (Bayerischer Rundfunk / HUK Coburg)

![VAG Hug [Trolling Mode]](https://www.autopareri.com/uploads/reactions/Volkswagencare.png.d8857dae0567cc6602dfdb1c9cbeb700.png)